The Rolling Division

The division manufactures hot-rolled flats, bars, rounds, angles and more, for both market sales as well as for captive self-consumption, wherein the forging division will proceed to fabricate finished, down-stream products.

The division manufactures hot-rolled flats, bars, rounds, angles and more, for both market sales as well as for captive self-consumption, wherein the forging division will proceed to fabricate finished, down-stream products.

In 2007, this tranche of our facility was modernized by installing a new Heavy 355 mm (14”) mill with five stands. The mill is driven by a 1000 Horse-Power Motor, which virtually doubled the plant’s productive capacity from its former strength. The company also undertook an agreement with Tata Steel Limited in Jamshedpur, wherein we supply their processing agent with about 12,000 metric tonnes annually.

Apart from that, the mill also rolls out approximately 17,500 metric tonnes for captive production in forging, which is done internally, and for sale in the local market. The Division Production for the year (ending 31-3-2012) was gauged at 13,400 metric tonnes.

Hand Tools & Implements

The following are the sub-divisions that constitute our departments of Hand Tools & Implements.

The following are the sub-divisions that constitute our departments of Hand Tools & Implements.

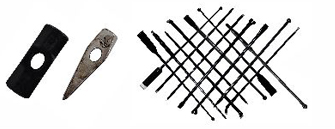

Pick (Kudali) Forging:

This is the oldest plant of our company and is responsible for the manufacture of Kudali’s and similar, allied implements. This plant has also been brought absolutely up to date with the installation of heavy duty presses and a new heating furnace which has greatly enhanced the plant’s capacity.The present capacity of Kudali manufacturing unit is about 650,000 pieces per year.

Bars Forging Plant:

This division manufactures various types of crowbars for home and domestic usage along with other special types of bars like Pinch Point, Post Hole, Wedge Point, San Angelo, Big Bars, and Telegraph Bars, which are primarily manufactured for export-houses.We also recently upgraded this division by establishing one of the latest induction bar-heating furnaces to bolster and increase production levels.

The unit is equipped to supply products of international quality.Tailor made grinding and buffing units are installed to give better finish to the products. These finished tools are then Heat treated by induction furnaces and powder coated. Thereafter these tools are packed in wooded pallets and exported to European countries.

Forging And Fabrication Division

As far as the Forging and Fabrication division is concerned, we have the following sub-divisions constituting this line:

As far as the Forging and Fabrication division is concerned, we have the following sub-divisions constituting this line:

Drop Forging Facility:

The Company already utilizes two hammers; with a capacity of one and two tonnes respectively, to manufacture special kinds of drop-forged, high value products.

This division also supports a rolling mill as it will also consume the rolled products.

Shivagrico Implements also entered into a conversion agreement with Tata Steel Limited, Jamshedpur to manufacture about 800,000 pieces or implements annually at the forging facility.